Xometry

Web App for Manufacturing

Problem:

Manufacturing is cheaper outside the United States, so for US machine shops, work can be hard to find. An even greater struggle is when shops are asked to quote a job, they spend time quoting and hope their competitors are more expensive. When the shop doesn’t win the job, money and man hours are lost.

Engineers and others who design and build assemblies need quotes from machine shops, which can take days, prolonging the project timeline. Some parts can’t be made overseas and finding a machine shop with the skills to make it can be difficult.

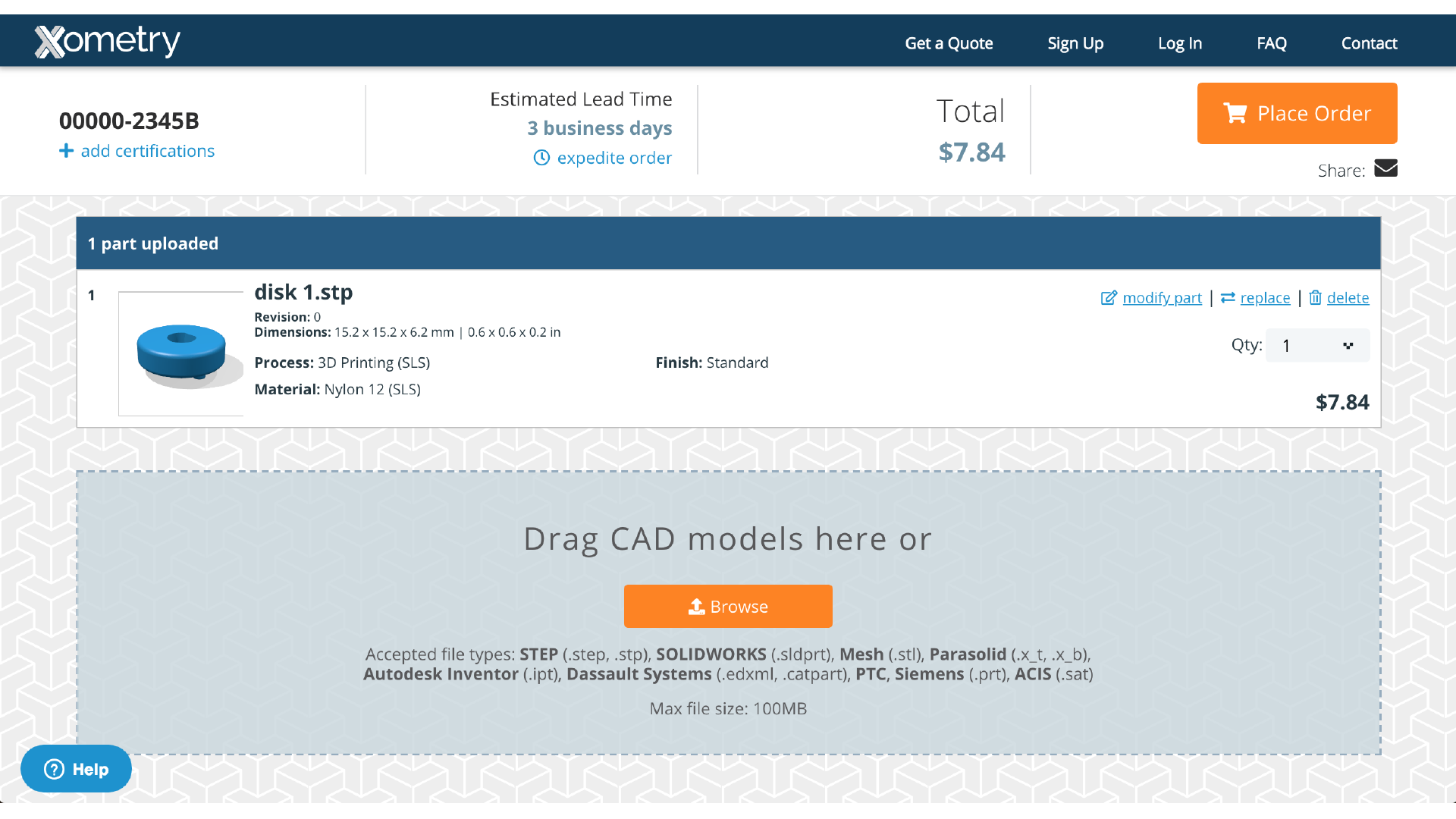

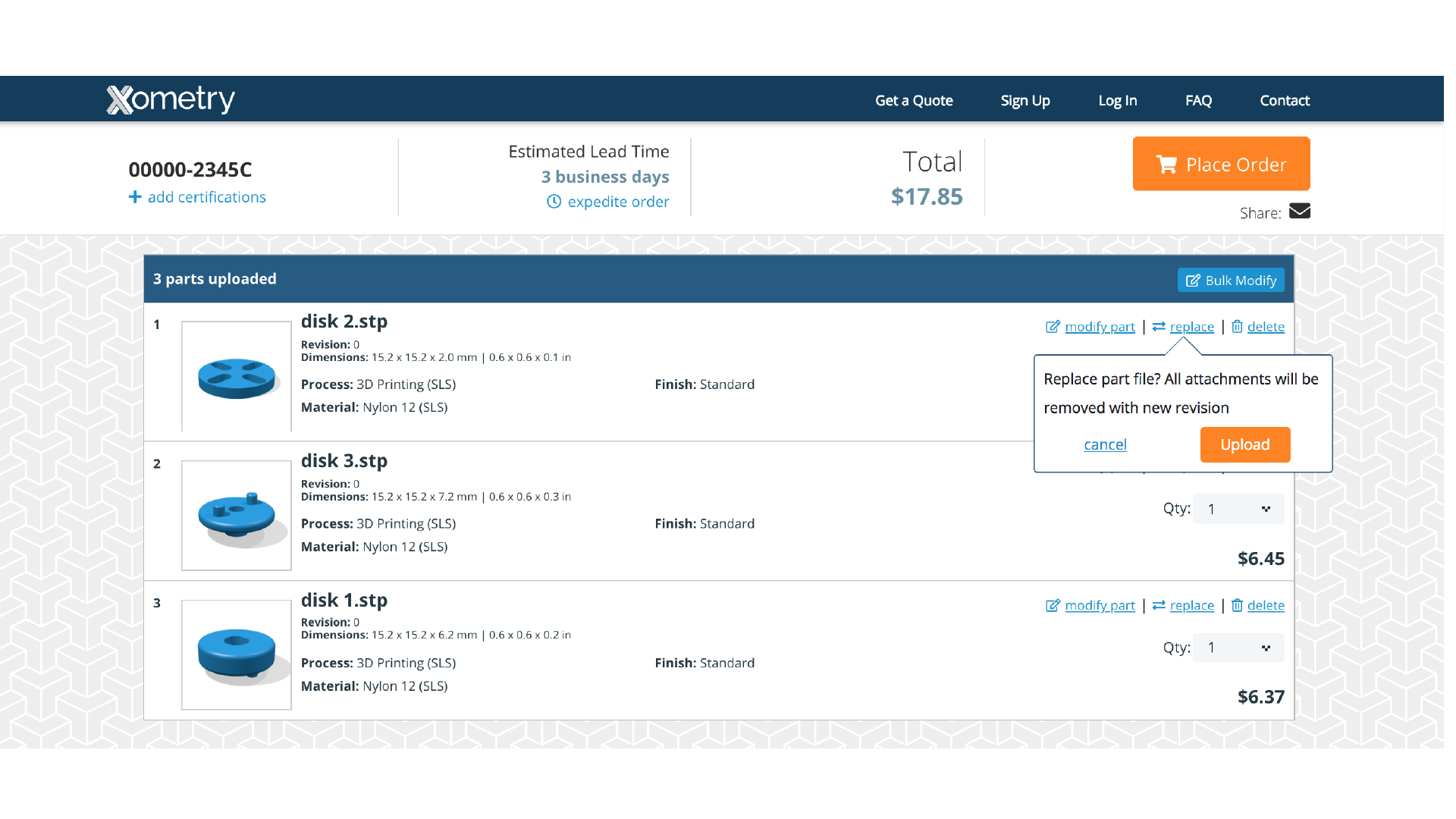

At Xometry, someone can upload a 3D model and receive an instant quote in almost every available manufacturing process and material. Using machine learning and algorithms, the quoting engine can read the geometry of a part and calculate how much it will be to make it.

Once a part is ordered, it’s sent to a vetted network of machine shops with a price, part details, and important instructions or information. Shops can then examine the job and determine whether it’s right for them. A shop does have to accept the job before another one does.

Ordering and manufacturing parts is made simple. Engineers don’t have to spend time researching shops and getting quotes. Machine shops are able to grab jobs without quoting and have the opportunity to machine jobs they normally wouldn’t.

Quoting Engine

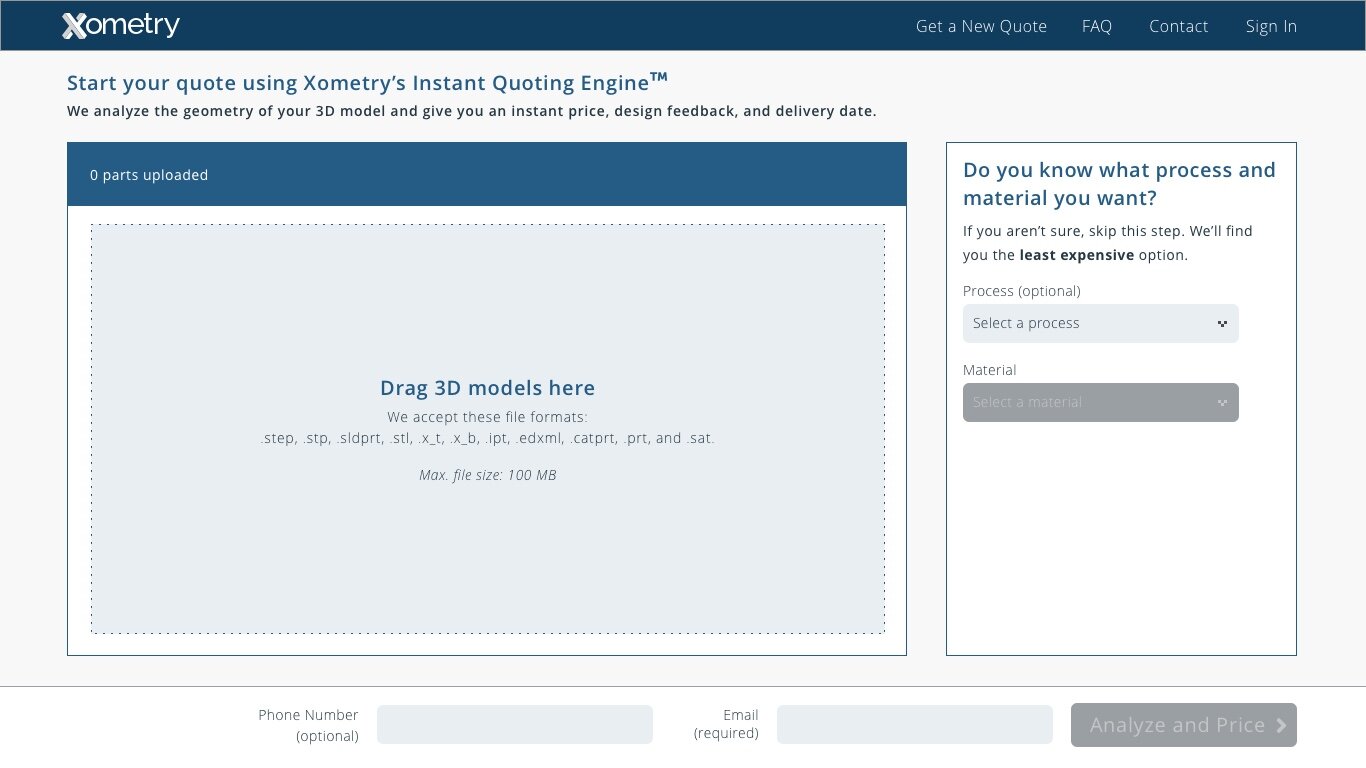

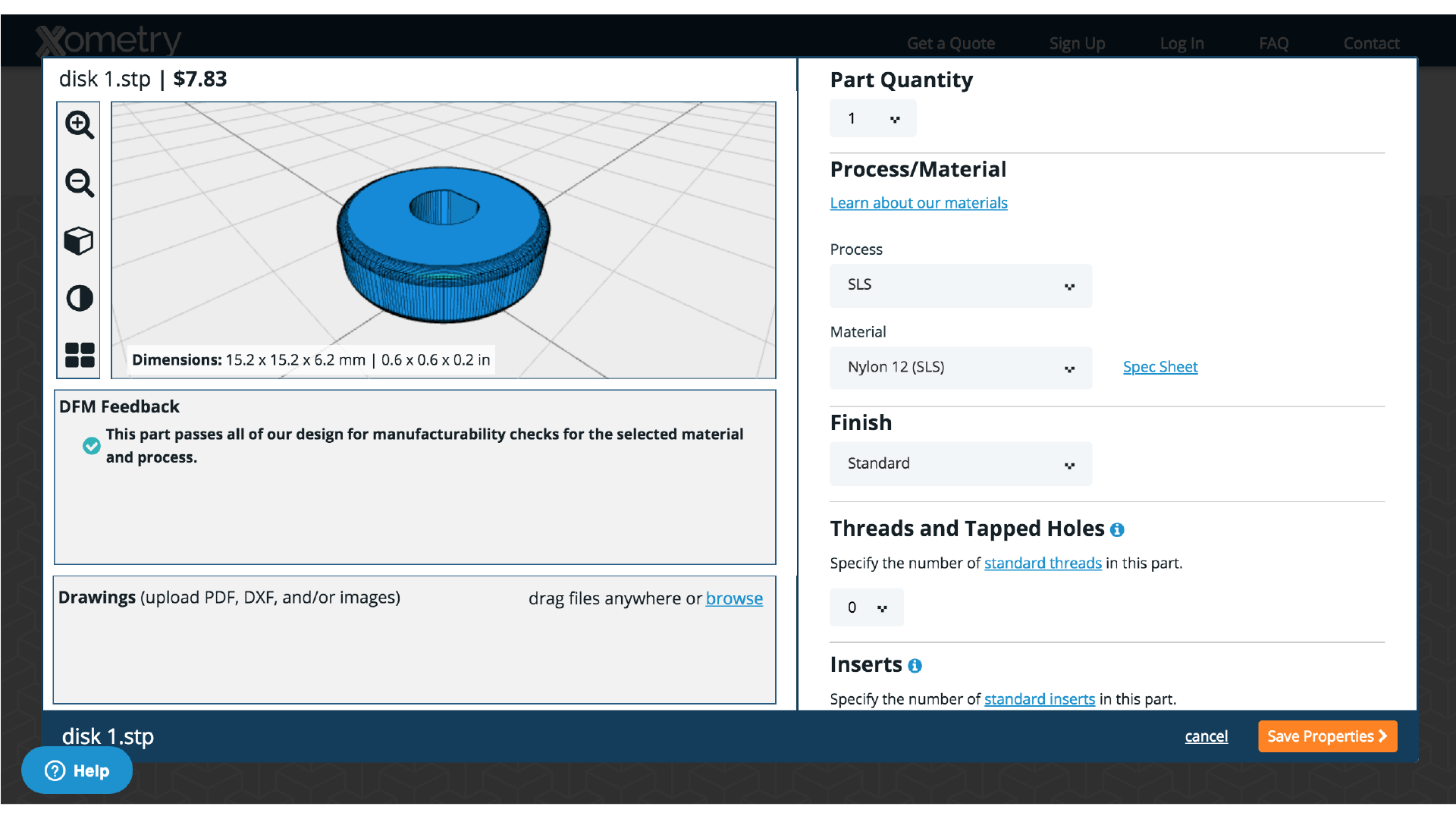

In order to give a customer an instant quote a manufacturing process and material must be applied to the part. The default rule is to quote the customer in the least expensive option. Customers could then change the process and material to what they want.

The original interface didn’t do a good job at displaying what was applied to the part. All the materials could be seen at once, which was an overwhelming experience. Especially for those who aren’t familiar with manufacturing.

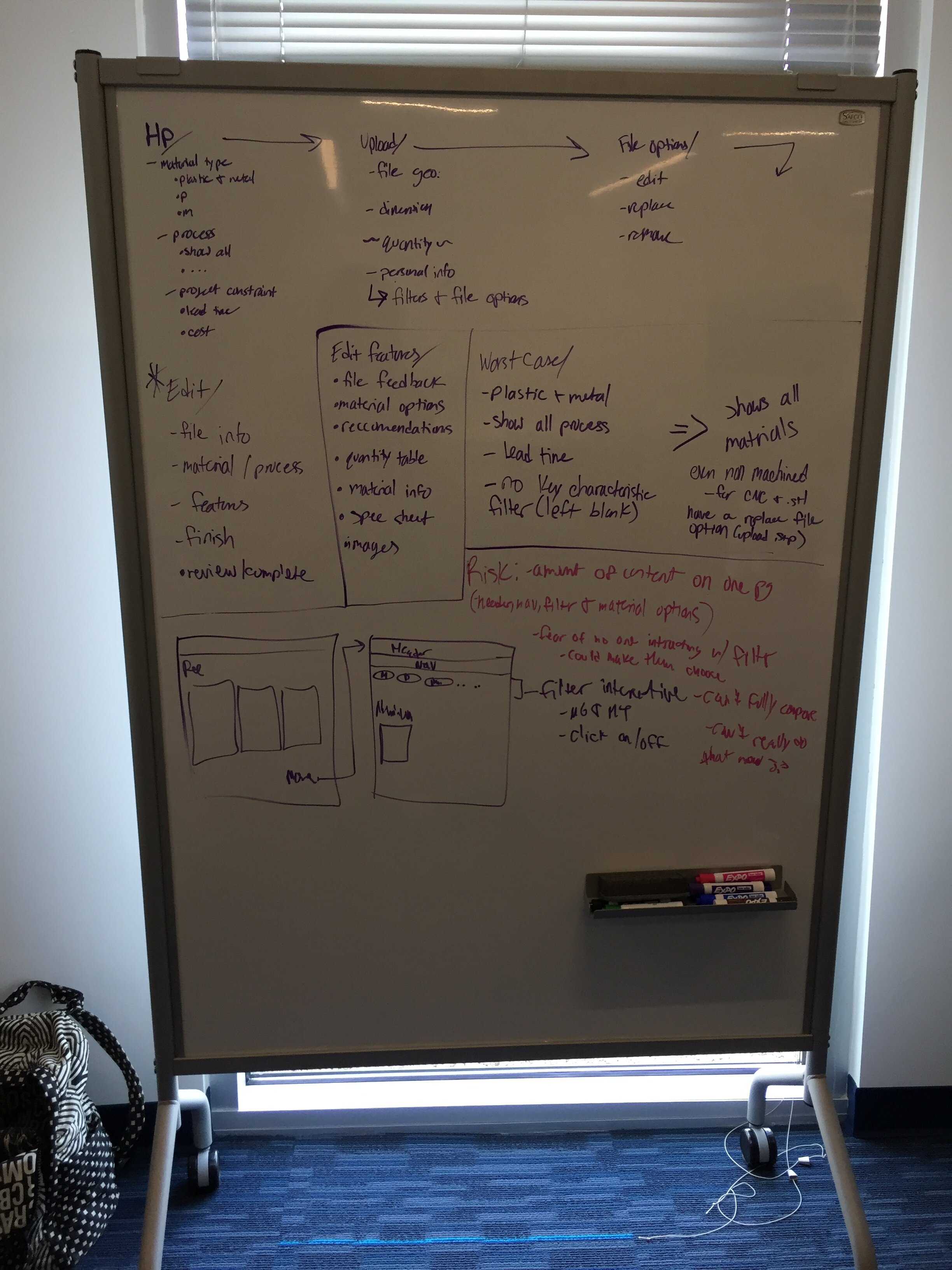

For my interview process and eventually first project I had an idea to ask customers what they wanted before getting a quote. My thinking was customers would be more delighted to see a price that is truer to what the final cost would be. Also knowing more about your customer upfront would allow for better recommendations and guidance.

After conducting user interviews I discovered there are two types of customers. Customers either know exactly what they need or they have a general sense of what they are needing.

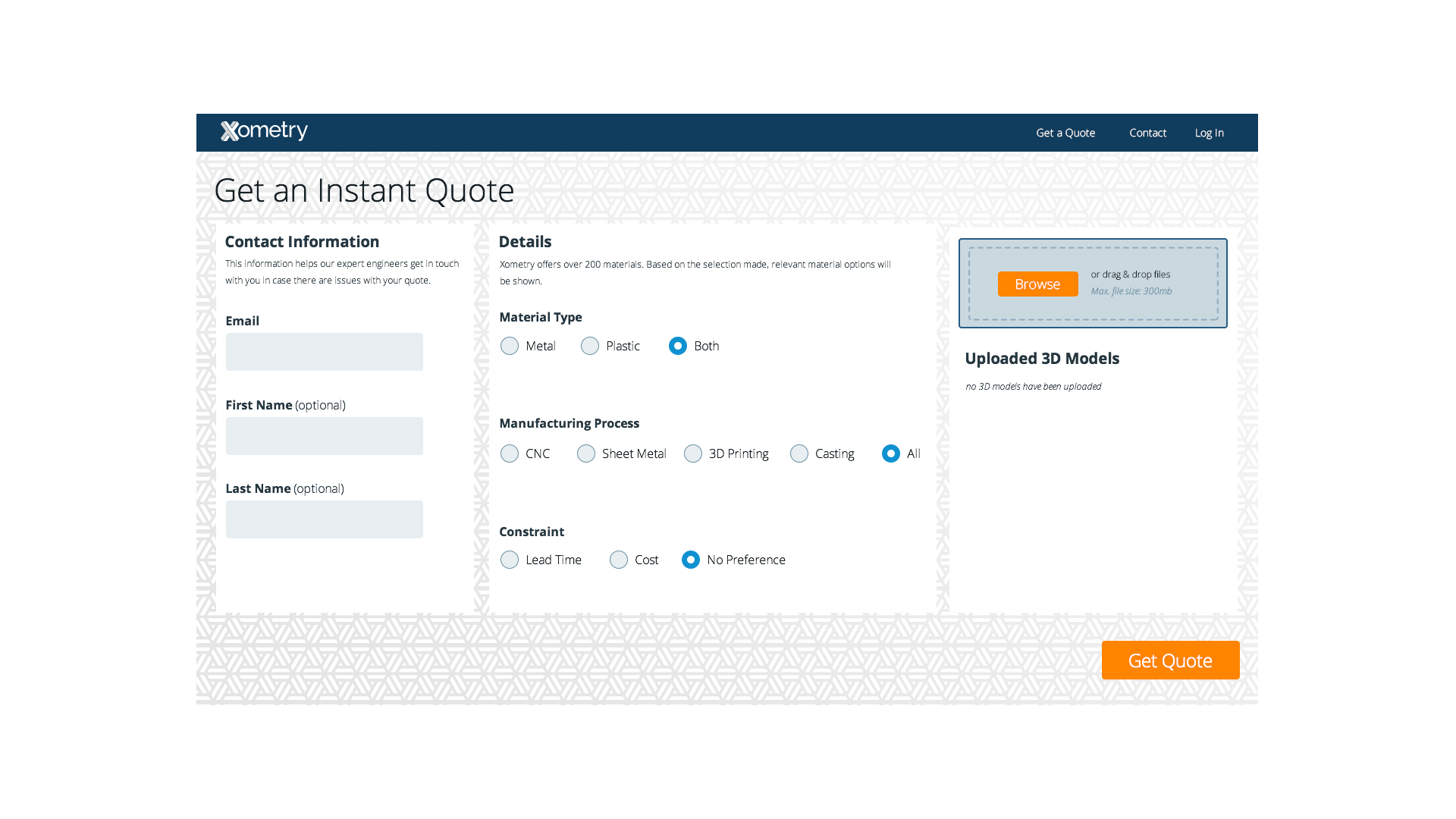

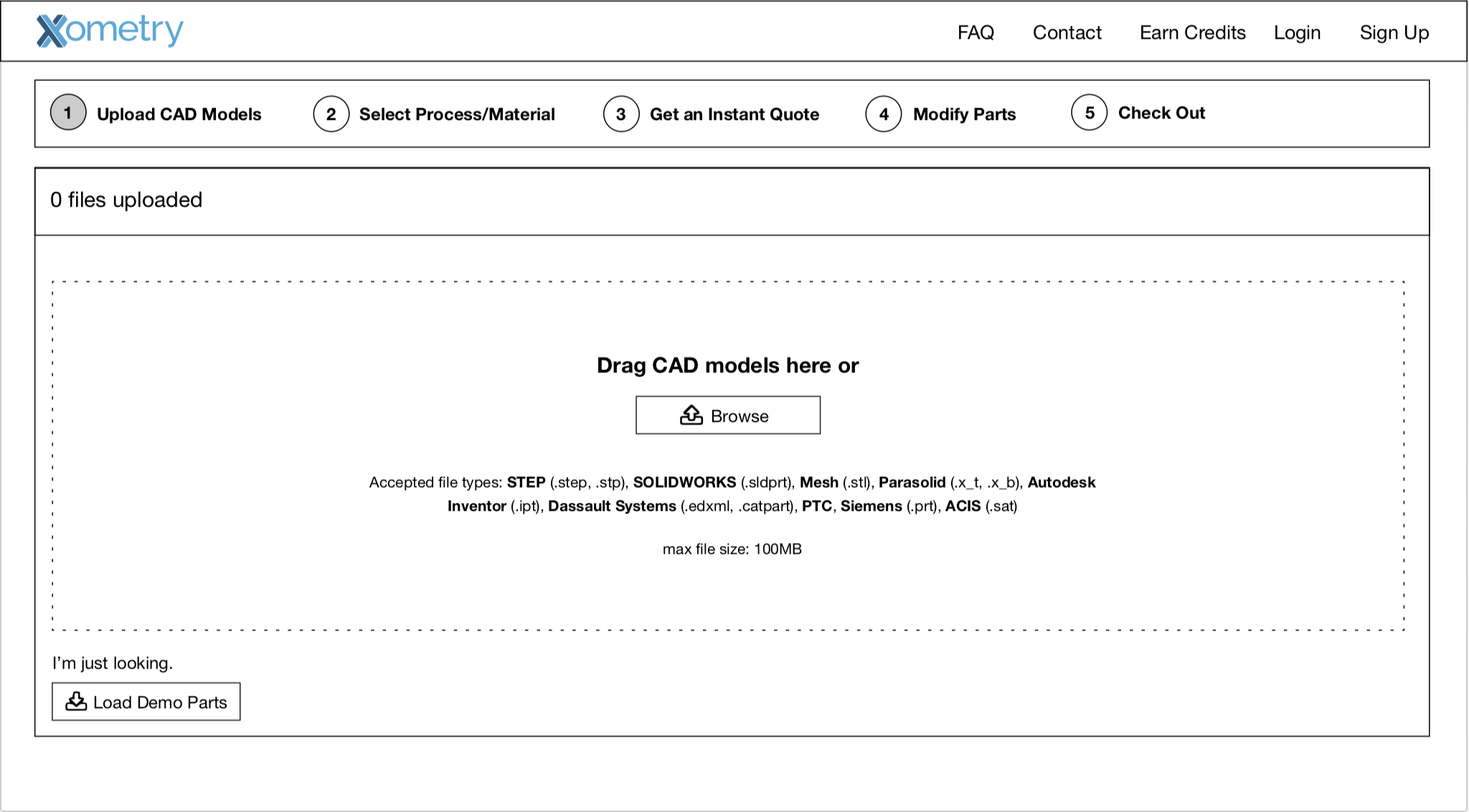

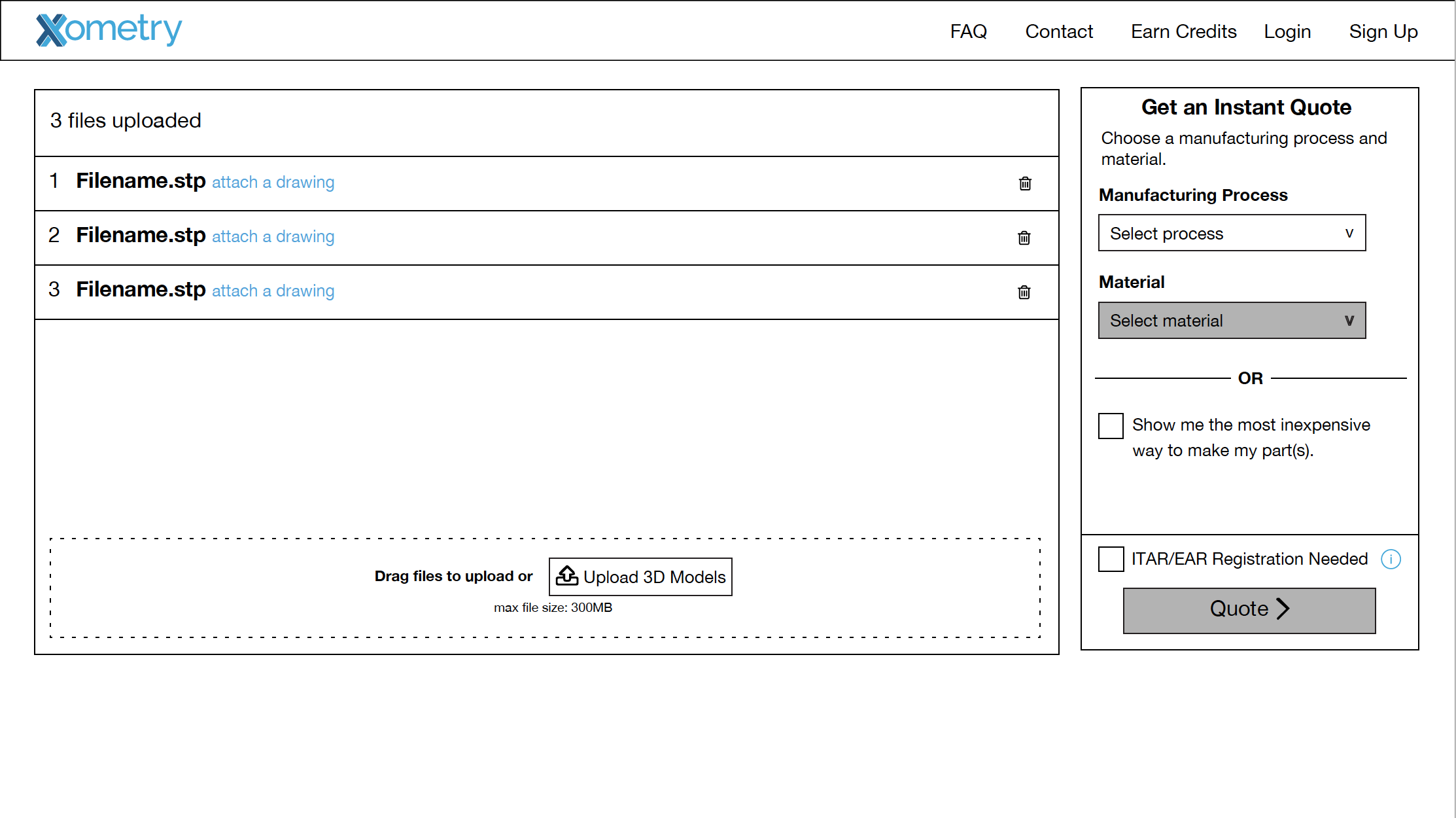

This lead me to design an intro page into the quoting engine that would allow the customer to upload files and tell the system what they wanted. For the three and half years I was at Xometry, the intro page went through two iterations and has contributed to higher quote conversions, brand trust, and ability to up-sell manufacturing opportunities.

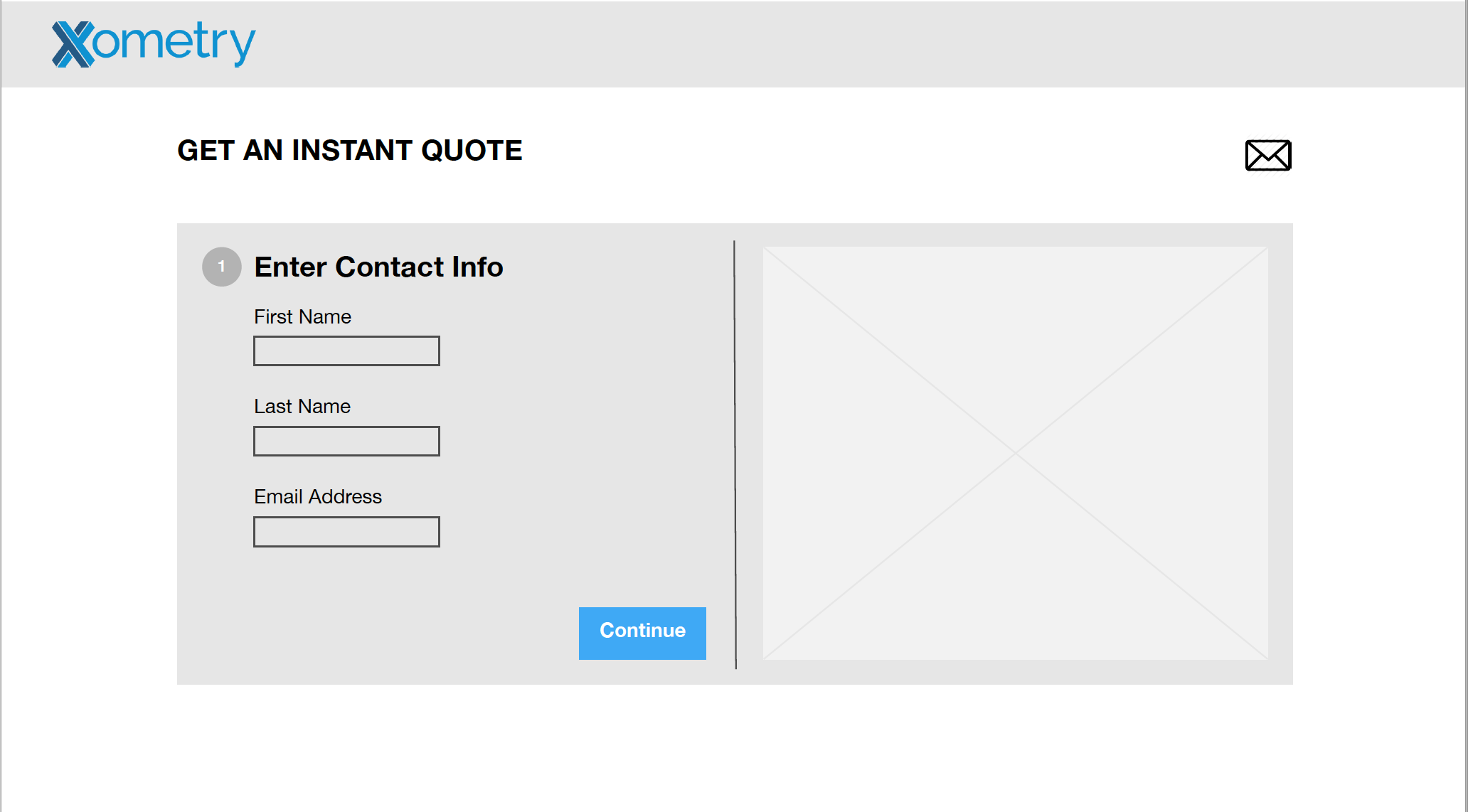

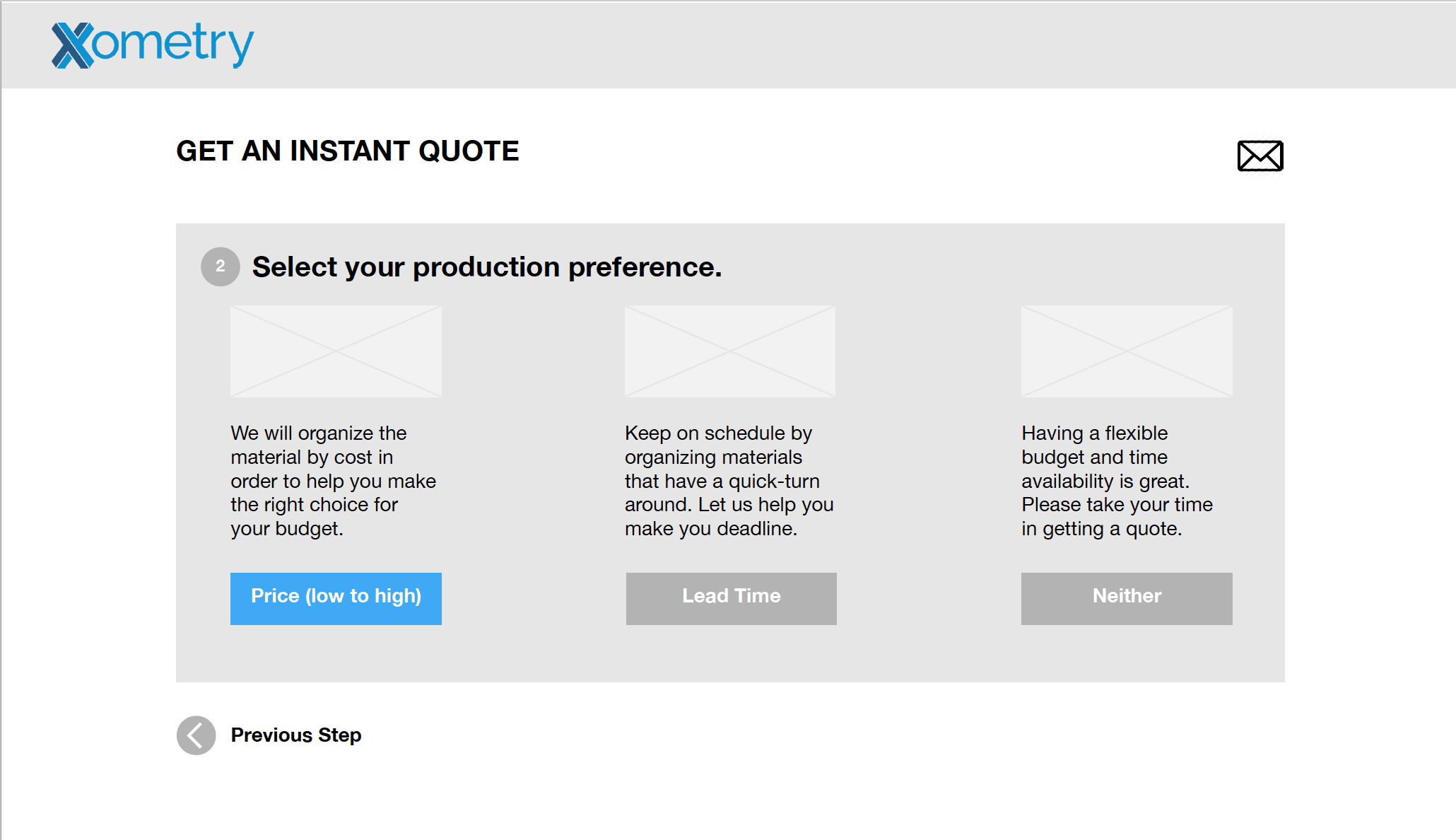

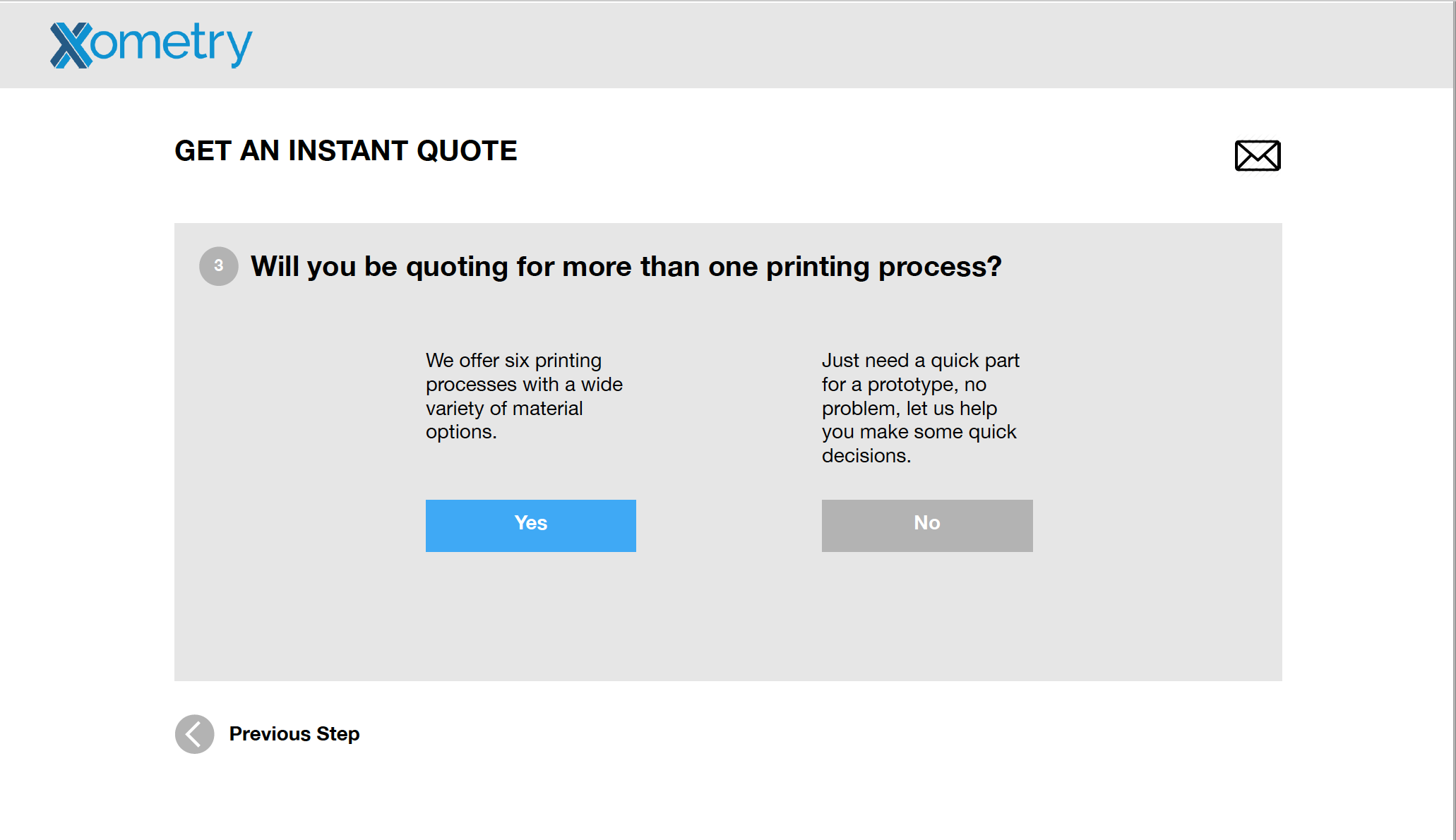

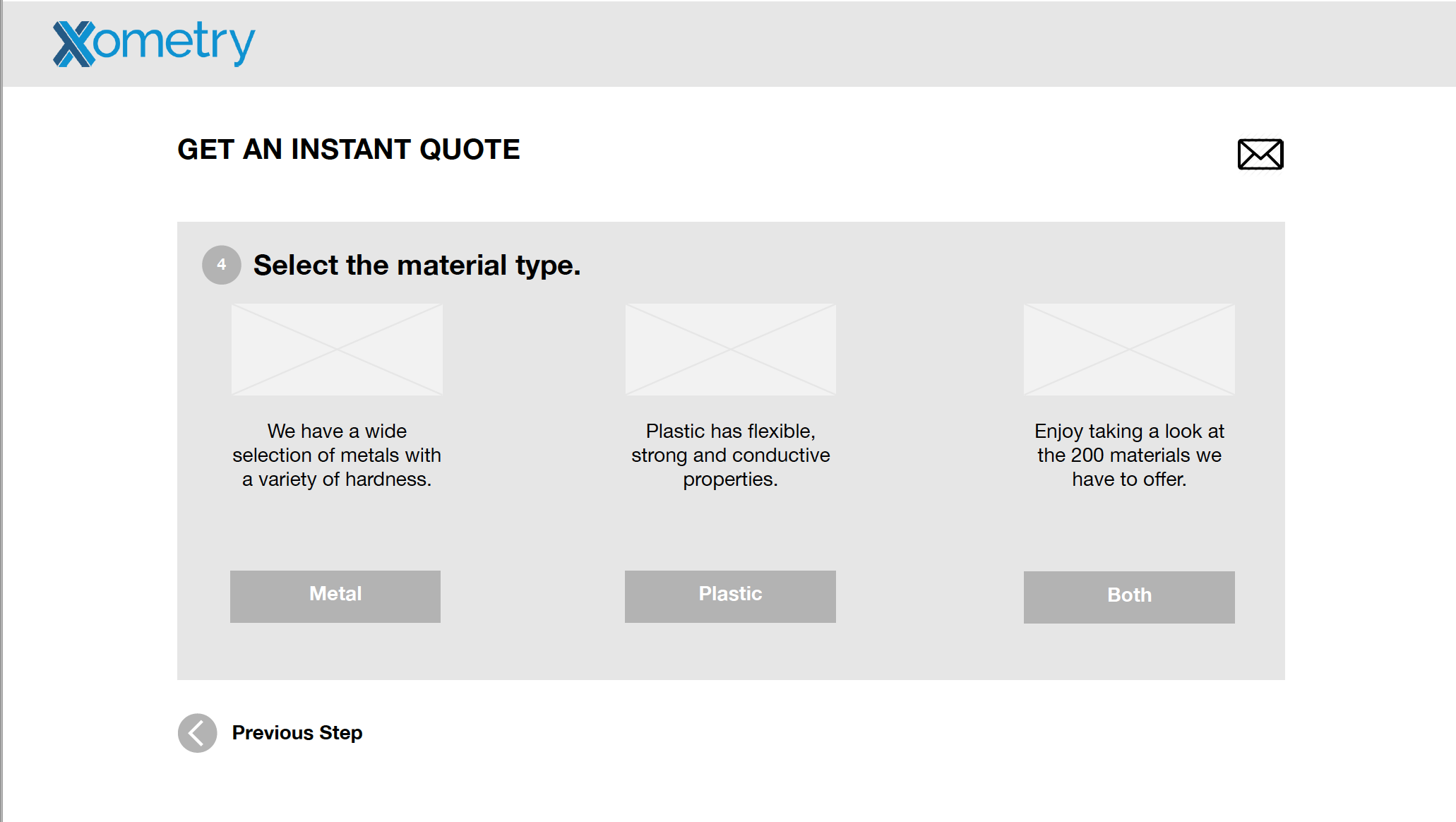

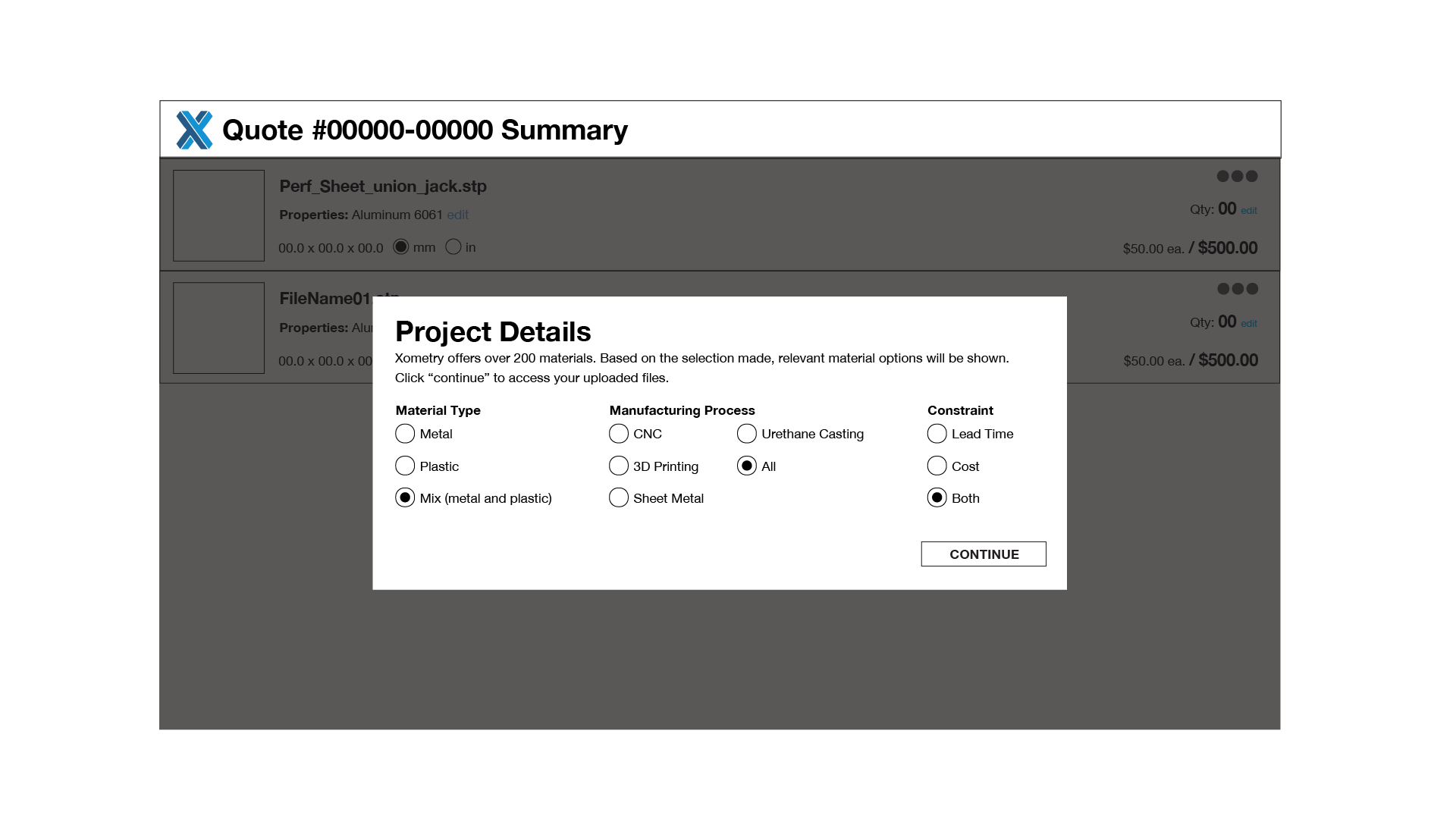

The first iteration asked three questions to help filter the process and material on the quote summary. It unfortunately could not directly ask customers what they were looking for because of the way the backend was structured. I came up with three questions that would filter the material options down, making it less overwhelming. These three questions can be answered by customers who know exactly what they want and by those who have a general sense of what they are looking for.

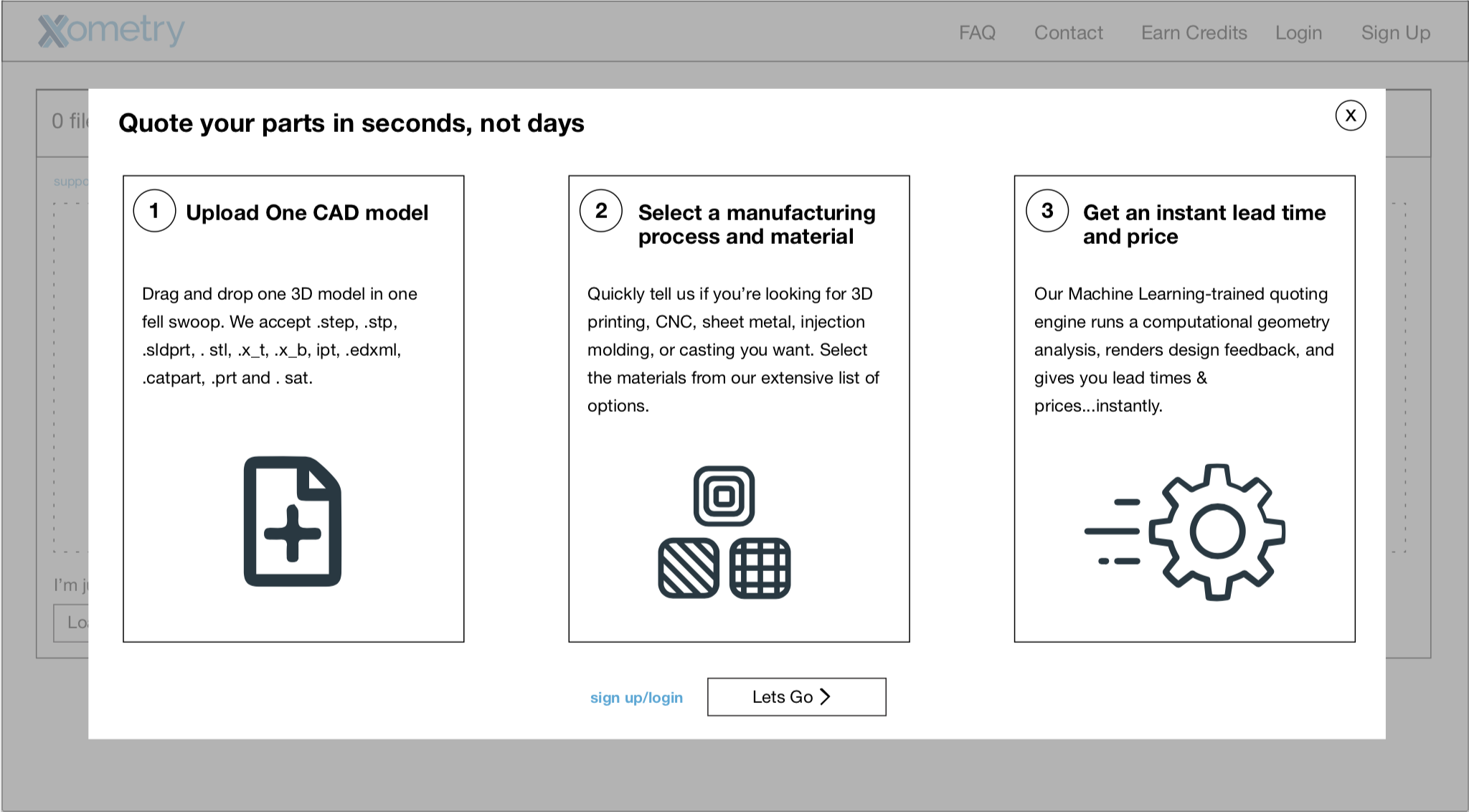

For the second iteration, the backend was rewritten to allow customers to specify the exact process and material. Majority of Xometry’s customers know what they need. The three questions were a barrier to getting a quicker quote. Also, when watching FullStory recordings, it was clear that customers were struggling with the them.

Xometry’s competitors do some form of this page or experience. However, this experience allows for more flexibility later on in the flow. Even though I’m no longer with Xometry I can’t wait to see how this intro page changes. It’s awesome to think that something I presented in my interview became a real and beneficial experience.

Machine Shop Network

Due to the network being a secured portal, I unfortunately can’t show many designs. However, I can share what steps I went through in order to better the portal.

Xometry has a machine shop, so when I first started I was there almost weekly. In order to diversify the research, the product team and I went on a one day Virginia road trip to visit three shops. It was enlightening and a lot of fun. From then on we made it a point to visit 3-4 shops in a quarter. Seeing the physical space and daily operations helped us understand trends we were seeing in the data.

When we couldn’t visit shops, we were picking up the phone and talking with shops to understand why certain jobs went wrong. For several projects, we remotely tested prototypes. I orchestrated all the testing efforts and reported findings across the company. The portal had horrible UX when I started and every design and experience was backed with tons of research and data. When new designs were shown to shops, they couldn’t wait for them to be developed.

Machinist have been the best user group I’ve worked with. They are brutally honest and are great at articulating their problems. I’m also a little bias because my brother is a machinist.

Redesign

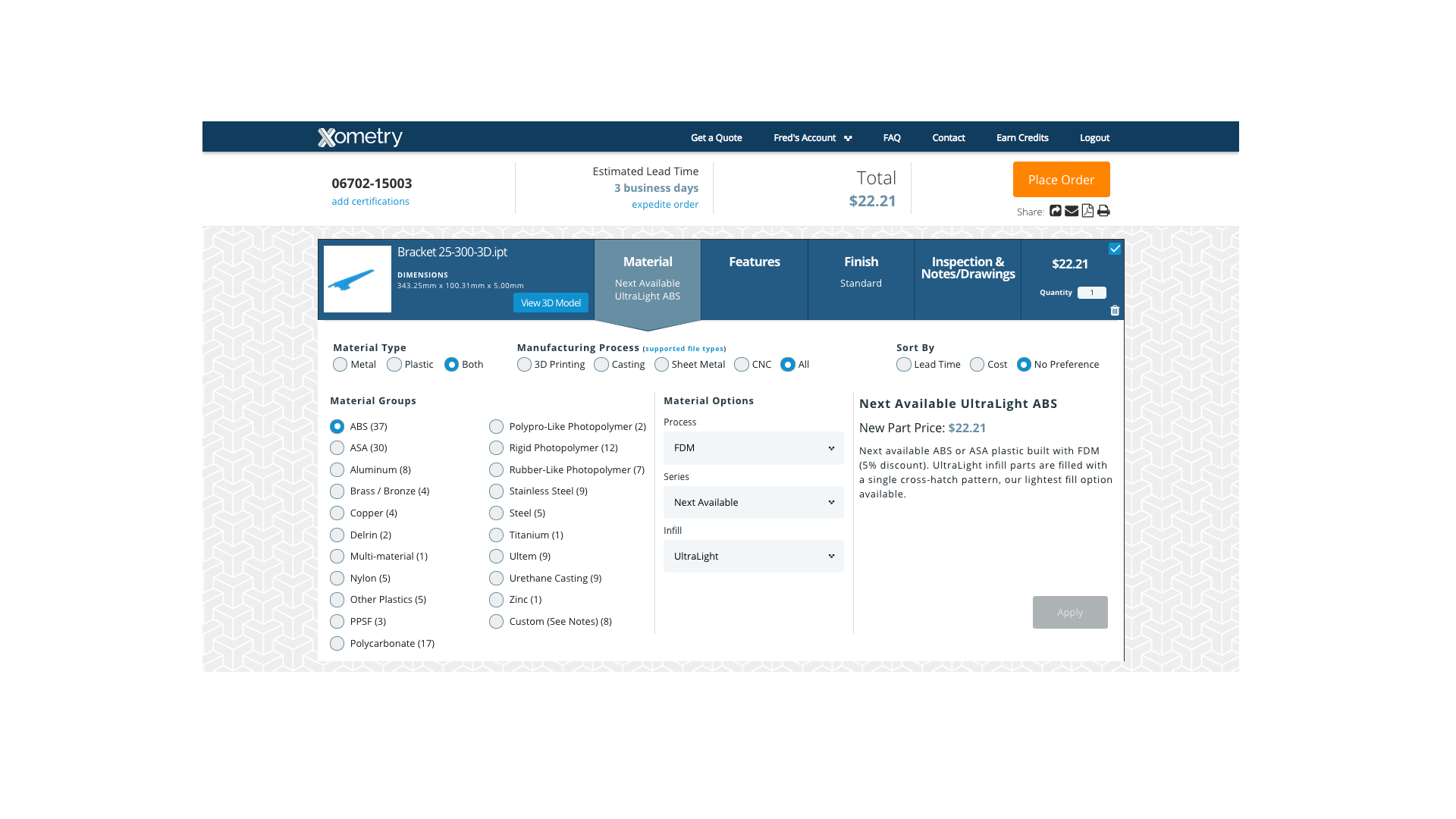

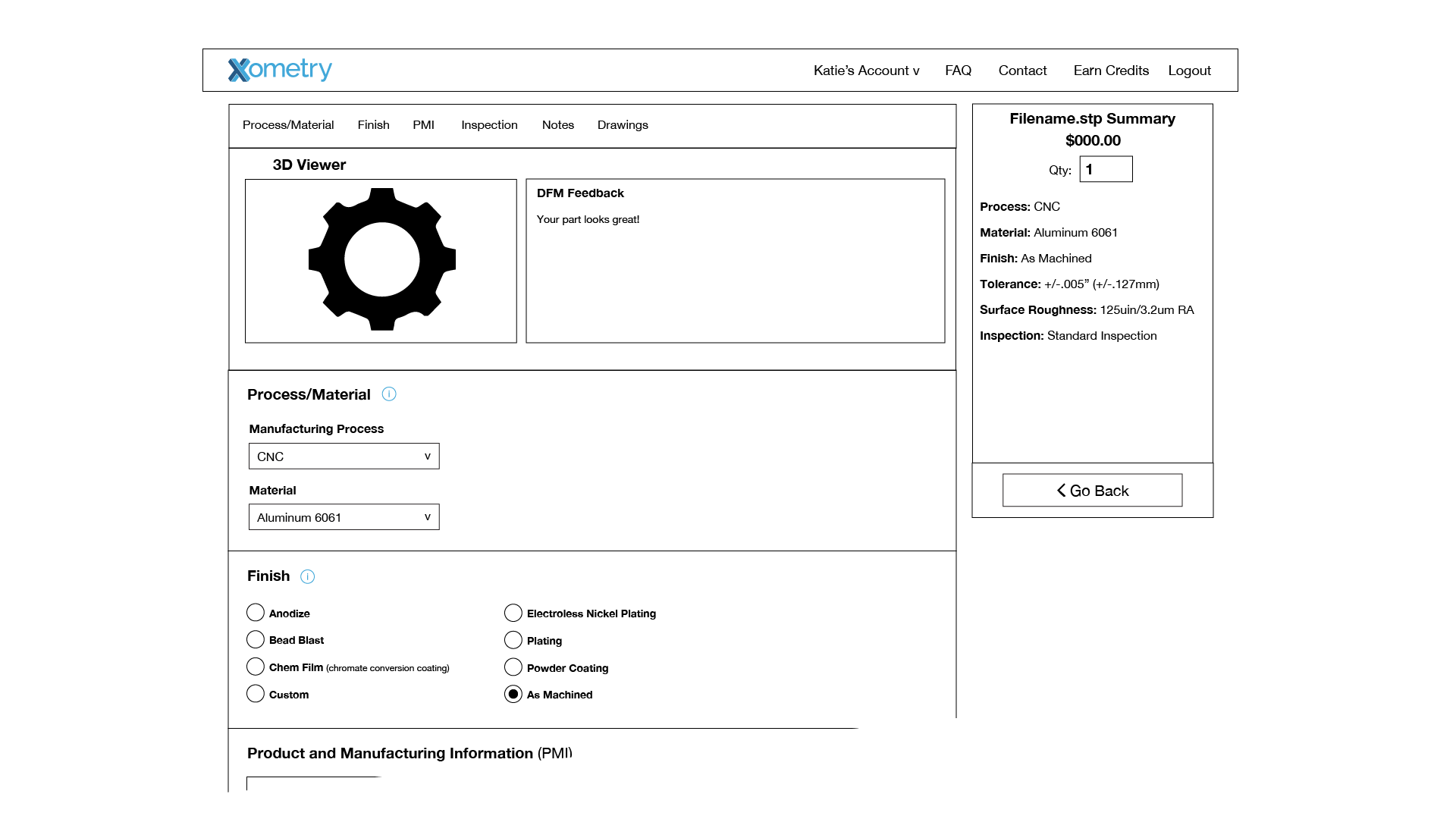

Lastly, the quote engine went through a redesign to better the styling and experience.

Business Goals:

Create an e-commerce experience that looked familiar to customers

Increase quotes and orders by creating an inviting and memorable experience

Increase visibility into what is applied to the part (process/material, finish, feature, inspection and notes) to minimize mistakes

Through user interviews and several different user tests, the product team and I arrived at an MVP solution. In addition to user research, I did extensive e-commerce best practice research and competitive analysis. Since complete product roll out, Xometry has broken several sales goals. Xometry has broken and continue to break most quotes in a day, the week we released broke the highest weekly revenue, and had the highest new company registrations in a week.