Xometry: Web App for Manufacturing

March 2016 - April 2019

Xometry is a manufacturing market place. Using AI, buyers can obtain an instant quote for parts in multiple manufacturing processes and connect directly with a manufacturing shop that will fabricate their part to specification.

This is an example of a job board used by the manufacturing shops to accept or reject jobs.

This is a screen of what the job details page could look like.

Use case 1: The Manufacturing shop

When a buyer needs a part fabricated, they will typically reach out to several shops for competitive quotes. The manufacturing shops can take days, sometimes weeks, to quote a job for a buyer. A lot of time is spent by the manufacturing shop to review specifications and quote both materials and work hours. Once the buyer hires a shop, the other shops who lost the bid aren’t paid for their time to generate the quote.

Unfortunately, I can’t show many designs of the manufacturing portal due to it being secured behind a members-only login.

Project Goal

Create a job board experience that allows manufacturing shops to efficiently accept and reject jobs. Saving them the time and money they would be spending manually quoting a job.

UX Research

Xometry owns a machine shop that is used for machine learning purposes. Many hours were spent talking to the machinist and understanding the general process of what it takes to quote and fabricate a part. On several occasions, I was able to visit machine shops in Xometry’s network to learn more about the inner workings and how the portal could better the machine shop’s workflow.

For several projects, the Product Manager and I would interview shop owners and remotely test prototypes. As the only Product Designer at the time, my main responsibilities were planning the research efforts, reaching out to shops, summarize findings into reports, and development-ready designs.

UI Design

Using Sketch, my typical design process is to sketch quick ideas based on user research and product metrics. Then turn the sketches into hi-fidelity wireframes that can be shared internally and with customers. Before designs go to development, they are validated with customers to ensure the solution is solving for a particular pain point.

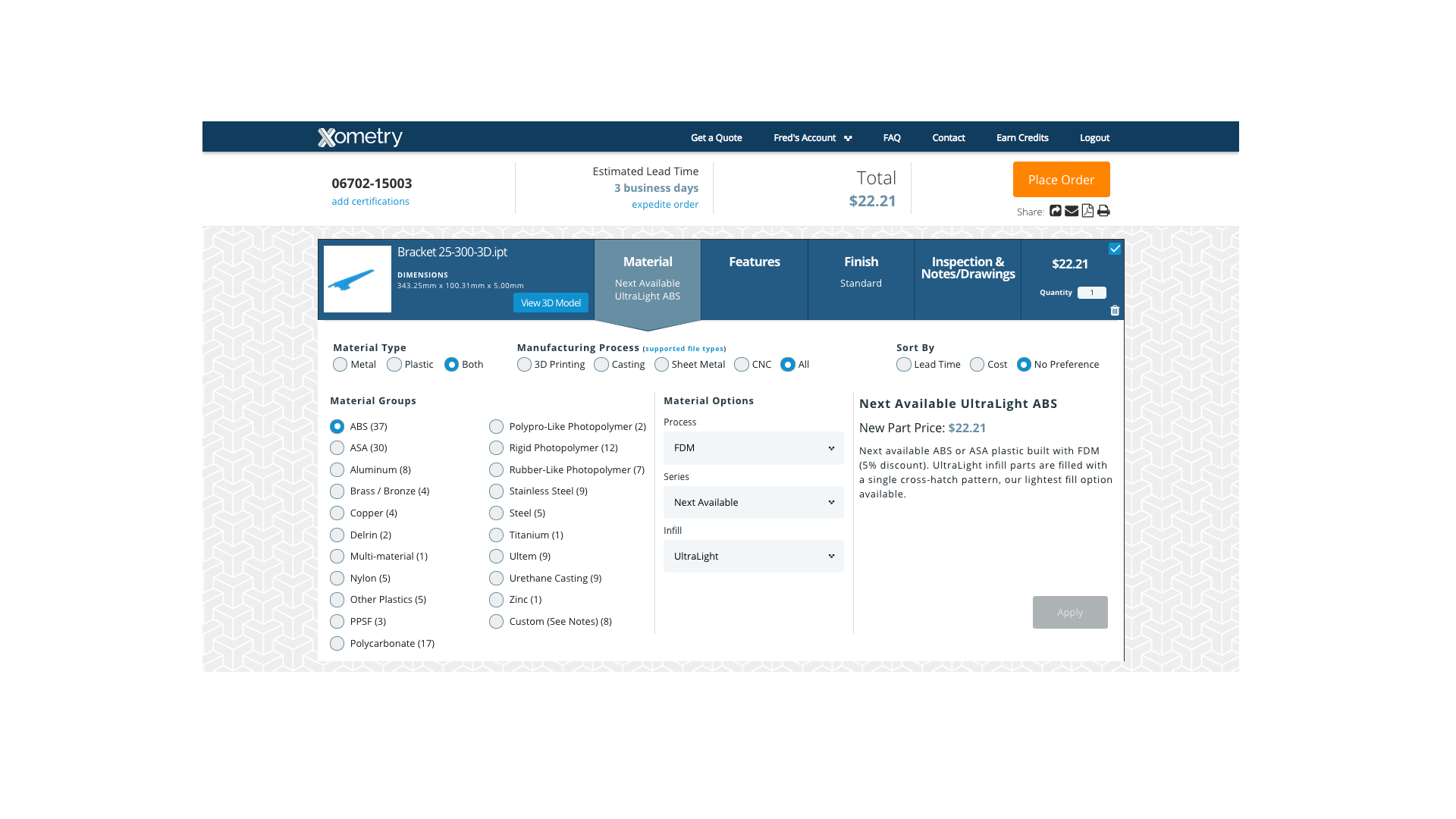

The quoting engine before a large overhaul of the quoting workflow.

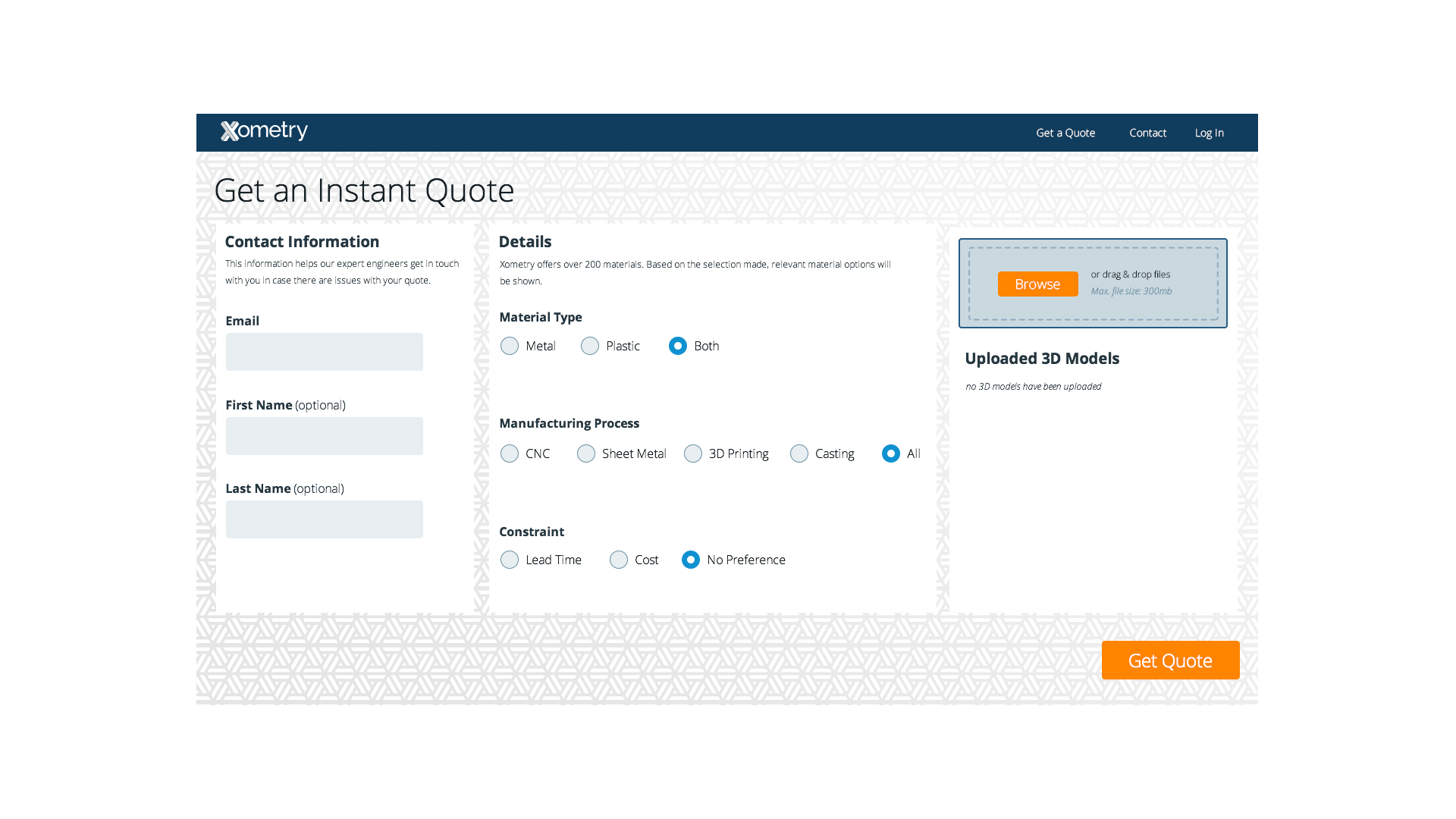

The first step in the new quoting workflow.

use case 2: The buyer

A buyer with a 3D CAD model needs to contact machine shops in order to get a quote and have the part fabricated. As stated above quoting can take days or weeks, which can prolong project timelines. Some parts can’t be made overseas, so finding an onshore machine shop with the skills to make the part can be difficult.

Project Goal

In order to give a customer an instant quote, a manufacturing process and material must be applied to the part. The default rule is to quote the part to the least expensive option. Customers can then change the chosen options to what they prefer. To solve for this, we provided a solution that presents the buyer with the best, most accurate price for their job in just a few key strokes.

Hypothesis

If the buyer is presented with process options, including how they want their part made, then they will be more delighted to see a comparative price that reflects a truer cost.

UX Research

After interviewing Xometry’s buyer personas, I discovered there are two types of customers. Customers either know exactly what they need or they have a general sense of what they are needing. The solution went through live A/B testing. In order to determine the winning design, we compared conversion rates and the time it took a buyer to see a price. For the three and half years I was at Xometry, this page contributed to higher quote conversions, brand trust, and ability to up-sell manufacturing opportunities.

Design A

Design B (Winner)